Where Comfort and Precision Begin

The foundation of every high-performance underwear garment lies in the quality of its fabric—and that starts with expert knitting. At our facility, the knitting process is driven by a combination of cutting-edge machinery, skilled technicians, and a deep understanding of yarn behavior and fabric engineering.

We specialize in knitting premium fabrics that meet the specific performance needs of underwear—whether it's breathability, stretch, durability, or softness.

Step-by-Step: Our Knitting Process

Yarn Inspection & Preparation

Every batch of yarn is thoroughly inspected for consistency, strength, and moisture content before it enters production. Proper conditioning ensures optimal tension and uniformity during knitting.

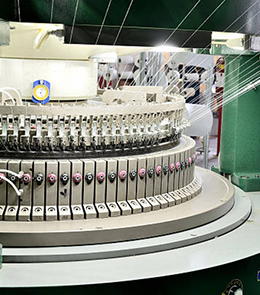

Knitting on Circular Machines

We use advanced circular knitting machines (single jersey, interlock, and rib structures) that allow for high-speed production while maintaining tight control over gauge, loop density, and stretch characteristics. These machines are ideal for producing seamless and smooth fabrics essential in intimate wear.

Quality Monitoring

Throughout the knitting process, in-line sensors and trained operators ensure the fabric meets our stringent quality standards. We monitor for:

Roll Formation & Inspection

Knitted fabric is rolled, labelled, and subjected to a second round of quality checks. Any imperfections are flagged, repaired, or removed before moving to the dyeing and finishing phase.